Smart Manufacturing

Full-automatic Chemical Dispensing, Sampling, Measuring, Monitoring of solution concentration, PH value, Conductivity and temperature. Avoid human errors.

Automatically collect and storage of parameter data. To be used for quality control, identify root cause to unsatisfied quality, improve production quality, achieve mass production goal.

Full-auto chemical dispensing, measuring and monitoring system

IPC Based Solution Measuring Algorithm Auto sample and measure chemical solution pH Value Conductivity (EC) Temperature Effective chemical Concentration

IPC Based Solution Measuring Algorithm Auto sample and measure chemical solution pH Value Conductivity (EC) Temperature Effective chemical Concentration

Functions

1

Full-auto remote measurement and data collection: pH, Conductivity, Temperature, chemical concentration, and other required parameters.

2

RS-232, RS-485, SDI-12(option), USB, or IEEE1394 communication

3

Adjustable parameter reference range, alarm, send information data to control center and mobile phones

4

Auto dispense of chemical and water, measure, clean, control, no human maintenance.

5

Touch screen display, no keyboard and mouse.

Technical Support line embedded, one touch to call customer service personal directly.

APPLICATION

- Surface Finishing – Blasting & Painting, Coating, Electroplating.

- Grinding, anodizing, Steel surface and other metallic surface finishing industry

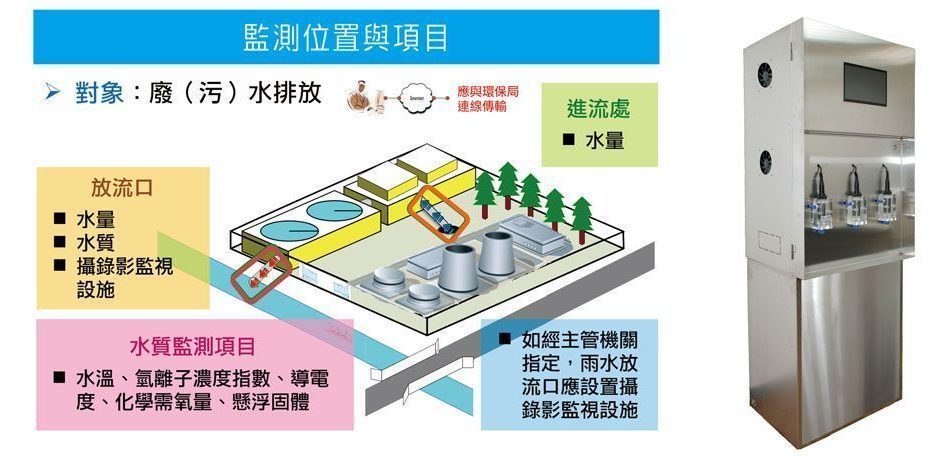

- Suitable for environment monitoring, like measuring source of pollution during sewage treatment

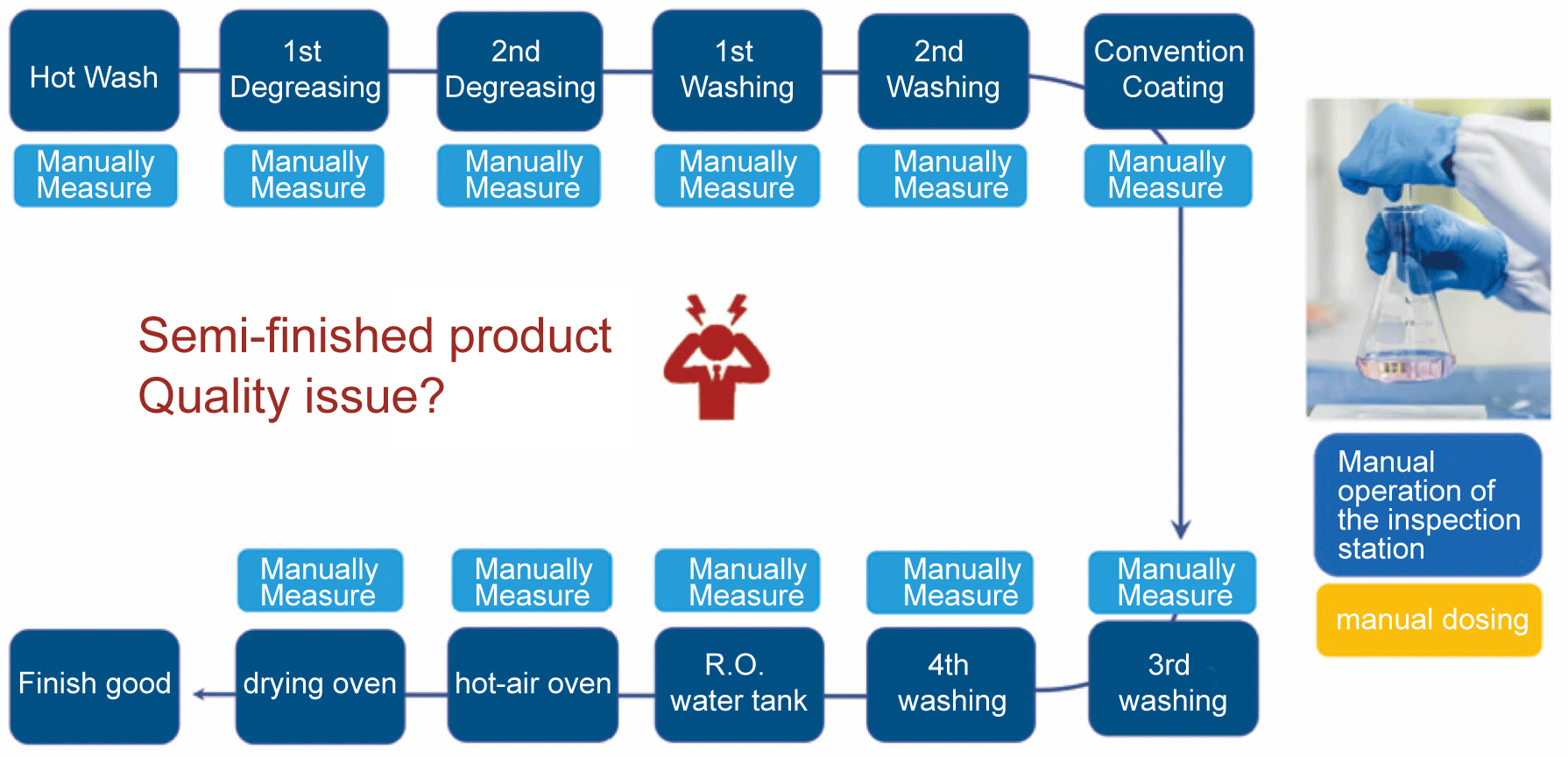

Have you found hidden problems in your factory? How to Resolve?

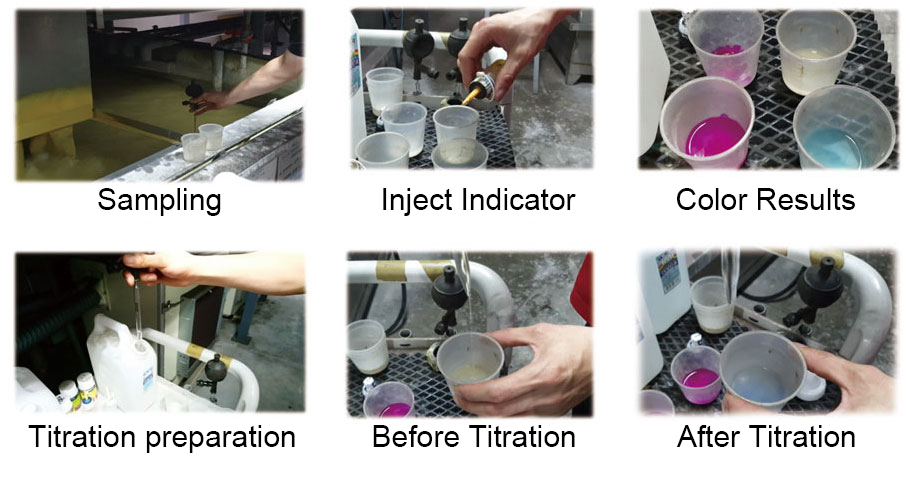

Production process, people forget measuring parameters of chemical solution, which causes inferior quality. Ex: Acid and alkaline value (pH), Electrical Conductivity (EC), Temperature, Chemical concentration.

Smart IoT Full-auto System

Before

Accurate parameter records have been always relying on experienced workers. They collect samples, send to examination station, manually execute measurement procedures following SOP, then record data on worksheet. Data will not be transferred to database for analysis until it has been accumulated to a certain amount. Real-time monitoring and improvement is impossible to carry through.

- Manually detecting chemical concentration is time consuming; data delayed and questionable.

- Manual Operation →

Likely to fail, data not real-time

- Quality Risk →

Risks shifted to QC due to insufficient tools

- Productivity Loss →

Labor, time and material in rework

- Capacity Bottleneck →

Risk on expansion, cap on economic scale, loss on revenue

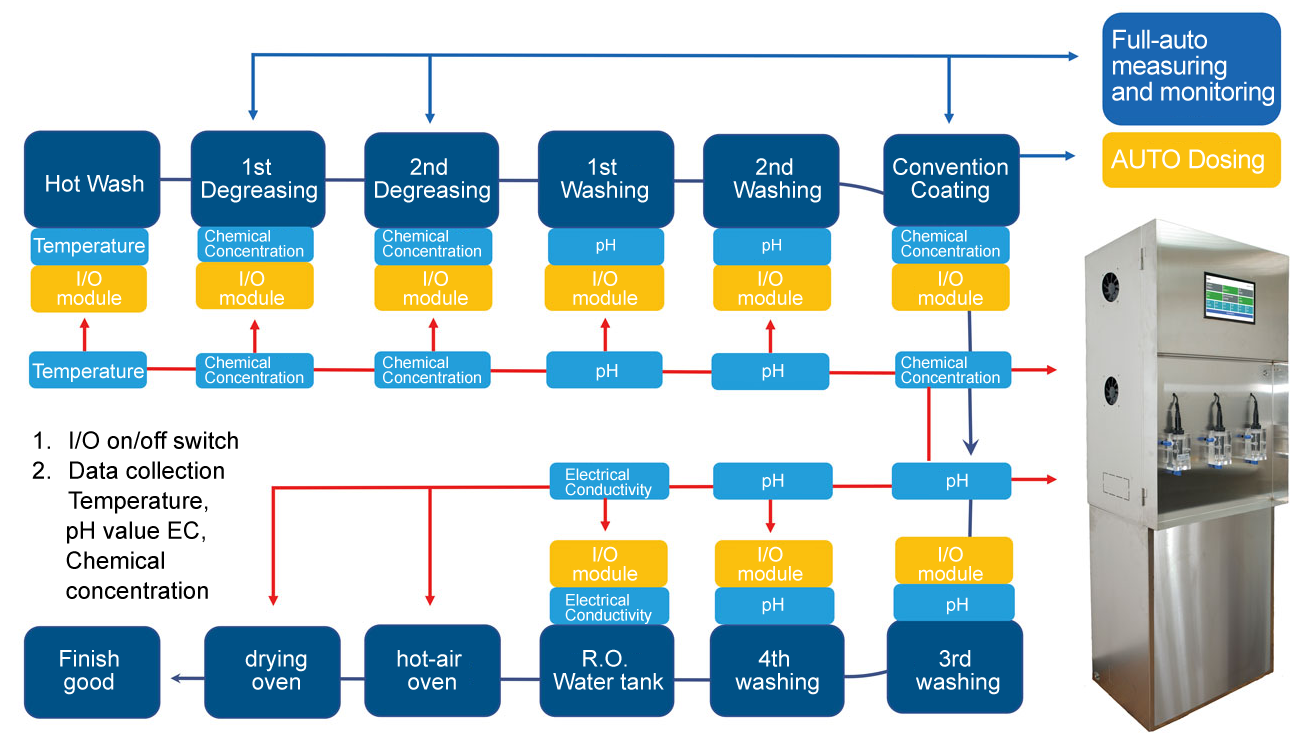

Smart IoT Full-auto System

After

SIFACD-MMC will automatically collect production data and send to factory command center. Time of data storage is up to 5 years. System could be upgraded with multi-parameter modules. Base on real-time and historical data, analyze connection between production parameters and final products, to improve quality control, maximize production capacity and achieve ultimate goals.

- No human error →

Automatic Machine is implemented

- Quality Risk Free →

Auto QC to eliminate risk

- Production Capacity →

Save on labor and material

- Production Expansion →

On-time order and delivery

SIFACD-MMC Smart IoT, Full-auto chemical dispensing, measuring and monitoring system

Comparison Table

Additional Specifications

- Timing, remote control, optional multi-sampling method

- Wide range, automatically draws sample for measurement directly, without additional sampling equipment

- Digitalized data collection, remote transmission function, real-time automatic upload of monitoring data, data storage and sharing

- According to different characteristics of the object to be tested, measuring accuracy and cost requirement, software can be customized with system detection methods and functions

- The system can store data for more than 5 years, and ASES technical service provides electrode calibration on a regular basis

- The system regularly self-cleans measuring equipments to prevent formation of sediments from affecting measurement results

- Intelligent fault self-diagnosis, automatic and convenient system management and maintenance

- Consumables items and sampling pipes are easy to replace with effective cost

APPLICATION

- Surface Treatment – Blasting & Painting, Coating, Electroplating

- Grinding, Anodizing, Steel & other metal surface treatment

SIFACD-MMC Smart IoT, Full-auto chemical dispensing, measuring and monitoring system

High Frequency auto-sampling and measuring

Auto pH measuring

Auto EC detection

SIFACD-MMC Smart IoT, Full-auto chemical dispensing, measuring and monitoring system

Auto measure chemical concentration, pH, Temperature, EC

Auto measure chemical concentration, pH, Temperature, EC

Self-Clean of measuring module

Malfunction self-diagnosis

Malfunction self-diagnosis

Multi-parameters online analysis of water quality

Multi-parameters online analysis of water quality

Multi-parameters online analysis of water quality