Latest News

IIoT, Industry 4.0

2021-11-28

ASES provides equipment rental services to our clients.

With 2 3 4 5 program, clients will be able to upgrade their system at very affordable cost.

No maintenance cost, No repair cost (up to 4 years warranty)

2021-11-20

Provide you FREE use of equipment for surface preparation process

World’s economy has suffered since Covid-19 pandemic. Increasing cost of labor and materials is happening in the entire manufacturing industry. Emerging technology upgrade becomes very critical to survive and stand-out.

Smart manufacturing and lean production are keys to this inevitable trend of industry 4.0 revolution.

ASES has proven successful cases for the past 500 days. It adopts killer-innovation technology in our system for the surface finishing industry. We are now offering partnership opportunities to serve the Australian market.

As a unique offering, we provide FREE validation of using ASES’ system for clients in their production line, which is expected to achieve:

Reducing labor cost

Reducing chemical use by 30%

Reducing WIP defect rate by 25%

No modification required on existing production line.

No purchase order required to use ASES system.

A 7-minute presentation for your company will further explain ASES’ solutions.

2019-12-20

Industry 4.0, Industrial Internet of Things (IIoT)

Few people have predicted that Industry 4.0, Industrial Internet of Things (IIoT), and smart manufacturing will reshape the manufacturing industry so quickly!

A few years ago, more than half of traditional companies had not heard the term Internet of Things (IoT).

Today, at least two-thirds of companies show they need right strategies and know how to utilize it.

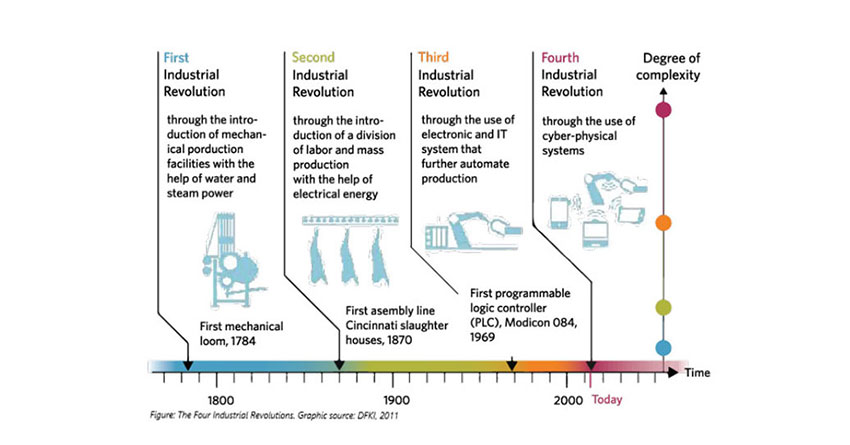

The Fourth Industrial Revolution

Centuries after innovation of mechanization and mass production, the third industrial revolution (Industry 3.0) introduced electronics, computerization, and automation into manufacturing industry. Production equipment can use sensors and industrial control devices to monitor and manage operations more effectively, but human error or decision-making by “feeling” still brings a huge risk to cost control!

In the past few years, the integration of physical equipment and digital information promoted by the fourth industrial revolution (Industry 4.0) has greatly reduced or even eliminated the risk of many human errors, through the Internet of Things and machine learning mechanisms.

Today, IoT technology can improve quality yield while also reducing cost (for example, increasing machine utilization, productivity, and reducing energy consumption).

In the past few years, two-thirds of manufacturers have improved their profitability through IoT!

Some leading manufacturers have moved towards the best practice of human-machine collaboration, benefiting from Industry 4.0 through advanced technologies and solutions!

In fact, all manufacturers can obtain benefits from Industry 4.0 and increase their productivity and profits through progressive and suitable IoT solutions.